safe handling of buggies

The problem:

Each year, the North American food processing industry loses millions of workdays due to work-related back pain and other musculoskeletal disorders. The most common causes of back pain are strained muscles or ligaments. One of the leading causes of back injury, especially in the meat processing sectors, is lifting and handling large pieces of meat and muscle.

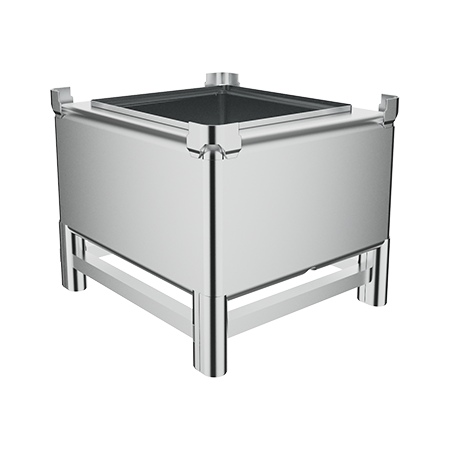

Working with stainless steel dump buggies: Stainless steel dump buggies come in both a 400 lb. (200 liter) and 600 lb. (300 liter) design, and are widely used in meat processing plants to transport various products around the production rooms. These products then need to be removed from the dump buggy and placed into further processing machinery such as tumblers, injectors, conveyors, cutting tables, or thermoforming-type machines.

Why use a stainless-steel dump buggy tipper:

- Small and compact footprint – These stainless-steel dump buggy tippers are designed with a small footprint and can easily be integrated into tight and compact working environments.

- Safe handling – The need for manual handling is eliminated, substantially reducing the risk of injury to employees.

- Mobility options – Stainless steel dump buggy tippers can be supplied in either stationary or mobile design with different chute arrangements.

- Dump buggy protection – Many dump buggies get damaged during manual handling scenarios. Operators often try to tilt them over to access the inside, which can cause damage or stress fractures to the top rim, creating a cavity or crack that’s difficult to clean and could harbor potential pathogens.

CM Process Solutions range of stainless-steel dump buggy tippers and tilters:

CM Process Solutions offers a complete range of tipping and tilting machines to handle your stainless-steel dump buggies within the production facility. These dump buggy tippers help reduce manual handling requirements, increase productivity, and streamline your production flow.

A smooth tipping action is controlled by a single stainless steel hydraulic washdown cylinder with push-to-operate buttons. They can be supplied in either a battery-operated or mains-operated design. Our dump buggy tipper model HT2 is designed to safely lift and handle a load capacity of 770 lbs.

Our range of dump buggy tilters are in stock and ready for immediate dispatch at our Winchester location in Kentucky. If you’d like to see one in person, our in-house demonstration center is available for you to visit and see our complete range of stainless-steel dump buggy-related equipment, which we call the single buggy solution.

Closing thoughts:

If you operate within the food processing industry, we’re confident that we can provide a dedicated customized solution to meet your individual requirements and help increase your production and improve efficiency while ensuring the safety of your employees.

Remember, investing in one of the CM Process Solutions stainless steel dump buggy tippers could be more cost-effective than a worker’s compensation claim in the long run.