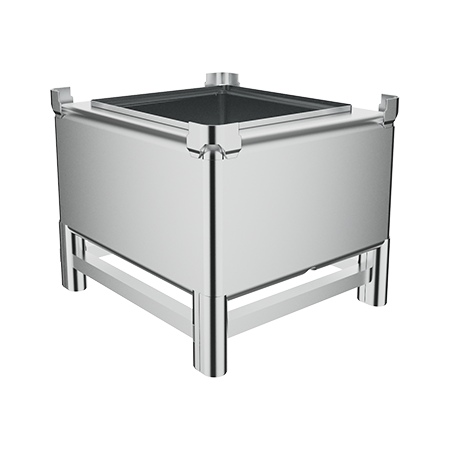

The Single Buggy Solution

From CM Process Solutions

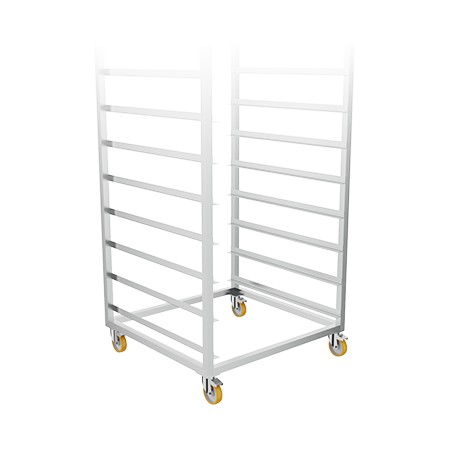

Dump Buggy Racking

Dump Buggy Weigh Scales

Dump Buggy Tumbler

Dump Buggy Tipper

Dump Buggy Lifters

Lift dump buggies up to a platform or second level using the versatile single column lifter. Designed to increase efficiency and eliminate manual handling from the lifting process. Compatible with both 400 lb & 600 lb dump buggies. This lift and dump model suits a number of different applications.

Dump Buggy Wash Frame

Our range of material handling equipment is designed to offer a complete solution for weighing, mixing and transferring product around the production areas with minimal input, followed by washing and storing of the v mag carts after the process.

The range includes a dump buggy weigh scale, dump buggy racking, dump buggy tumbler, single column dumpers or dump buggy tipper or tilter followed by a washing solution, be it an automatic dump buggy washer or manual dump buggy wash frame.

The single dump buggy solution helps streamline production and offers increased hygiene and sanitation benefits, because only one buggy is used for the entire process giving the producer more control, it also means that only one v edge buggy is emptied and washed at the end of the process, this in turn means that the ingredients and product within the dump buggy have minimal exposure to the risk of cross contamination caused by multiple buggy transfers that could bring them in contact with foreign bodies, residue waste or food allergens such as gluten, lactose or peanuts.

A lot of the bulk handling and time consuming labor intensive processes can have negative effects on the productivity and the morale of staff, coupled with the risk of employees suffering from potential musculoskeletal injuries caused by repetitive lifting and moving of dump buggies.

As one of our customers recently said utilizing equipment form the Single Dump Buggy Solution would be cheaper than a workers comp claim and increase productivity on the factory floor.