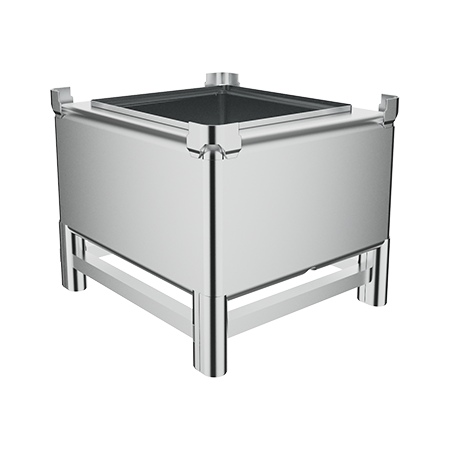

CM Process Solutions Launches New Industry Focused Website

CM Process Solutions is proud to announce the launch of its new website! Our goal is to provide easy access to the latest technology, solutions, and information needed to keep your business running smoothly.